|

|

|

|

|

| The Making of The Lewis & Clark Trail American Landscapes Book. |

|

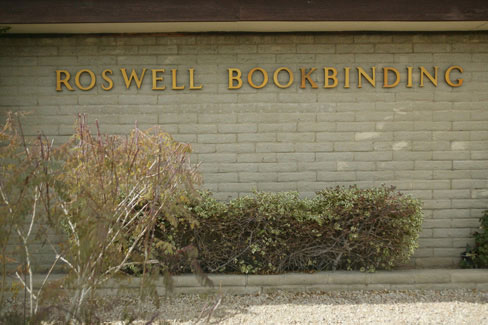

| Roswell Bookbinding, Phoenix, Arizona - February 16, 2005.

A book is a very personal thing for an author, or in this case the photographer. You spend time, years, making the images, doing the research, writing the text and this is done for the most part as a solitary thing. Then you hand this off to the designer, the printers and then the binder. It is then you realize how many people will really be involved with the production of the book. I thought I was understanding this fact. Then I walked into Roswell Bookbinding and the reality hit home. About 70-80 people will be involved with the binding of this book. It seemed like almost the entire place was working on it, although I know this was not the case. As we toured the production area everyone was happy to tell us what they were doing. It also was interesting to hear how long people had worked there, 20-30 years was not unusual. Everyone was also and artist at there job, whether it was in the stitching area, the gluing and binding or the making up of the boards. Each took pride in what they did and the results show that pride.

Roswell Bookbinding has bound some of the finest books in the world. Many of you probably have some of their work on your shelves already. I am honored that my book is now among there rooster of books.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

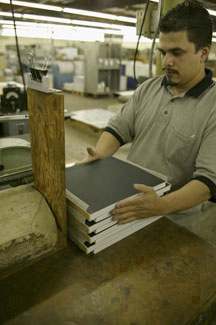

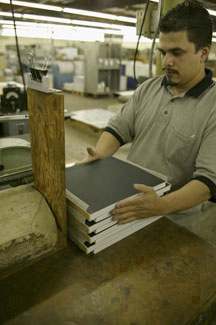

| The first part of the process we saw was the making of the cases. It takes four people to assemble the pieces, after each individual piece is made. They start with the front and back boards, glue on the black spine cloth, and must place the spine cardboard in place. They have various jigs ready to make sure the spacing on everything is perfect. They work down the line and can finish about 1200 per day. We have 10,000 books. |

|

|

|

|

|

| Gluing down the back piece of the spine cloth. |

|

|

|

|

|

|

| Gluing in the spine board with templates for positioning. |

|

Della inspecting a finished piece. |

|

|

|

|

|

|

| Marti the mini-moose couldn't wait to stand on them. Rich decided to carry him the rest of the way.... |

|

| Here they sit waiting to go into the bindery area. Stacks of book cases. |

|

|

|

|

|

|

|

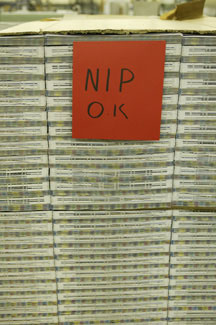

| After the pages from Stinehour are cut and folded they are placed in stacks to be collated. We have 21 signatures in the book. Each must be put in place correctly. |

The collated pages are then stacked on skids and wrapped for protection until they go to the stitching area. |

|

|

|

|

|

| The stitchers grab one signature at a time and place it carefully in the sewing machine. Each signature is sewn to the one before it until all 21 signatures are sewn together. |

|

|

|

|

|

|

|

|

|

| On the backside of the sewing machine someone gathers the bottom of the book and keeps it from jamming the machines. |

|

|

|

|

|

|

| Because of the size of this books they must all be sewn by hand on these machines instead of the automated machines. There are at least 3-4 people working at each machine to keep the process moving and to spell one another. |

|

|

|

|

|

| Rich inspects a book after the sewing stage and then Della inspect Marti the mini-moose.... |

|

|

|

|

|

|

|

|

| The sewn together books put into a press to extract all of the air from between the pages and are then glued along the spine. Then the books are put though the trimming machine and cut to the final trim size. |

|

|

|

|

|

|

|

| We have a ribbon in the book which is placed in next, one person checks each book to make sure it is facing the correct direction, one person inserts the ribbon, one glues and trims each ribbon and one tucks the end back into the pages. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Marti the mini-moose really enjoyed the ribbons and decided he needed one. |

|

|

|

|

|

|

|

|

| Next another piece of cardboard and fabric is placed along the spine to reinforce the binding. |

|

|

|

|

|

|

|

|

As the book sections go through the machine the glue is applied along with the stiffener fabric and then the header and footer ribbons, which in this case are the Quiet Light gold color. Then the finished pieces are stacked carefully. |

|

|

|

|

|

|

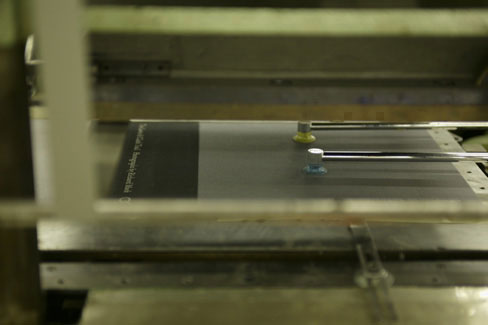

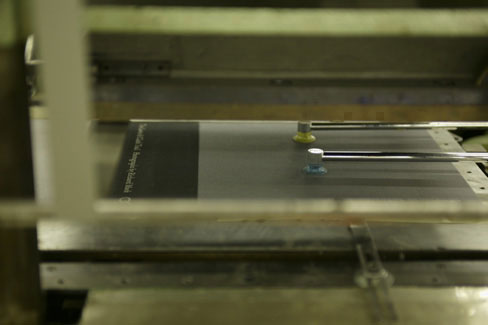

| The casing now has the spine imprinting applied. It has to be done after assembly to make sure it aligns with the spine correctly. |

|

|

|

|

|

|

|

|

| I checked out a few as they came off the machine while Eric checked out another big stack. |

|

|

|

|

|

| Now that all the pieces are made it is time for the casing in and final binding. Another round of glue is carefully applied to the end papers. The woman here has been doing this for years and is the best at knowing the exact amount to apply. Then the case is carefully placed over the pages and aligned to the pages. This is all done by hand. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| The books are then sent through another machine which creases the spine and applies pressure. The books are finally bound! |

|

|

|

|

|

|

|

|

|

|

|

| When Rich went over to talk to this fellow, he said to Rich, "Hey that's the guy isn't it?" Rich had to admit, finally, I was the guy. So when I went over, he said to me "I know your the guy, I saw your picture on the dust jacket. How's the weather back in Evanston?" And then he added "and you live with your wife two kids and three dogs!" So at least someone's reading the dust jacket. He told me it would only take another day to finish scribing all 10,000 dust jackets. He was putting a scribe on the folds of the jacket. I wish I could remember his name, guess he's better at that stuff than I am... |

|

|

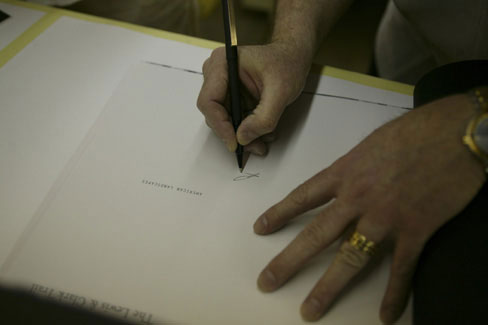

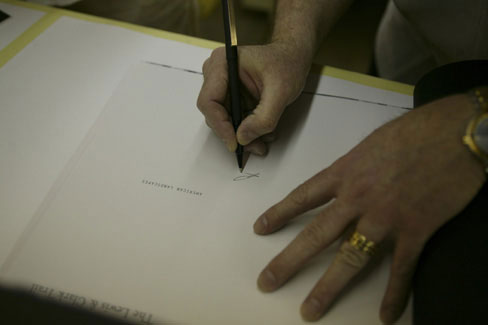

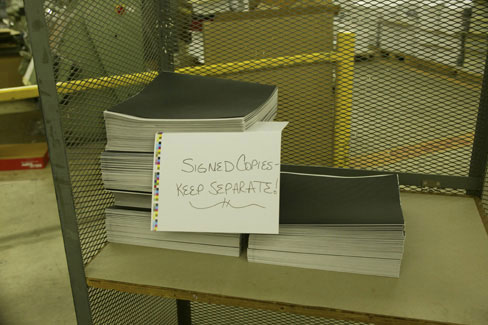

Because we need signed copies ready to go for the stores and orders we have already received we decided to sign about 500 books during the binding process so they would be finished and shrink wrapped ready to ship. The folks at Roswell had an area setup for me to sign the first signatures before they were stitched in with the rest of the pages. This took a few hours. But once we got the system down it went well. Both Rich and Kathy helped me out. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mike Roswell, Richard, Rich and Craig Thomas, who is in charge of the Trade division, discussing things in the production area. |

Mike Roswell and me discussing books and the market for them. Mike has been a great person to work with in the short time we have known him. I am looking forward to a long relationship with him and his company of artists. |

|

|

|

|

|

| Finally it was time to say good-bye and head out to see some of the sites of Arizona. To see Some of the fun times use this link to Marti the mini-moose sees Arizona. |

|

|

| Return to Main Pages. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|